Wildlife Laptop Sleeve

R795.00 – R925.00

Surely the best-looking laptop sleeve out there that doesn’t cost the earth – literally or figuratively.

Surely the best-looking laptop sleeve out there that doesn’t cost the earth – literally or figuratively.

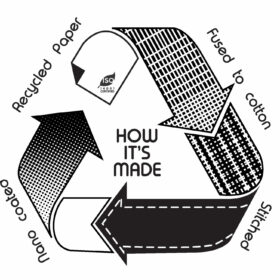

– You can feel good about your sleeve that is made from reclaimed, upcycled or recycled paper.

– Fused to cotton for strength.

– Digitally printed original artwork

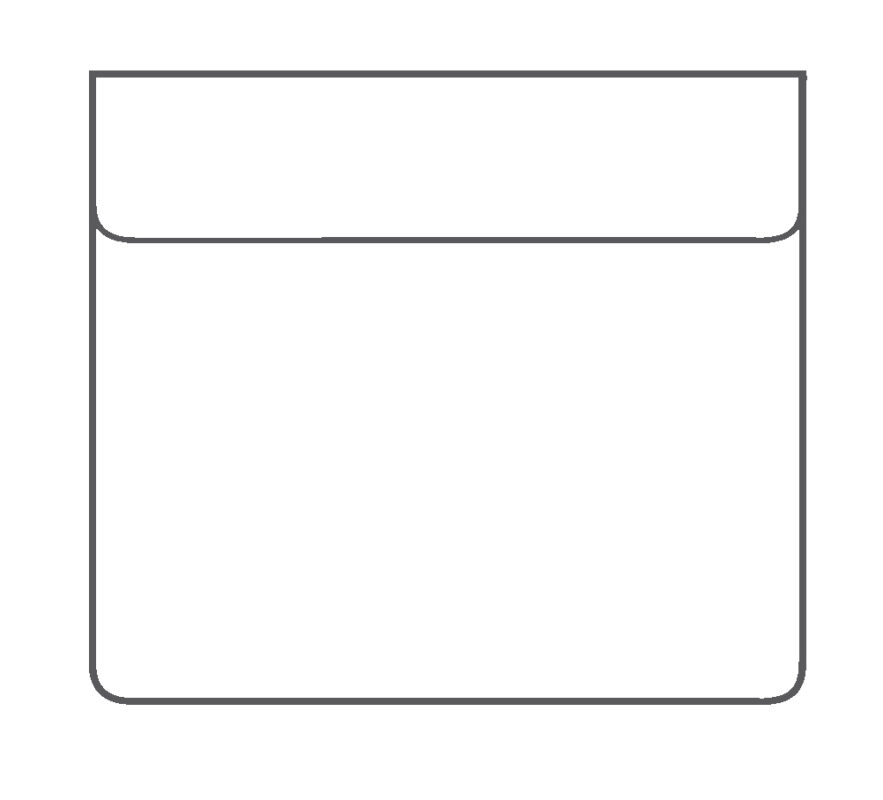

– The main interior pocket is padded and soft to keep your laptop scratch-free.

– There is a second front pocket for notes, notebooks, cables, or anything else.

– Protected from the elements with an environmentally friendly water-resistant coating (read more here).

– Closes easily with hidden magnets & a central press stud that provides a strong closure, ensuring that your laptop is kept safe.

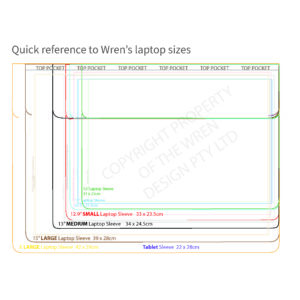

– Designed to fit many different laptops – View the full-size chart here

DESIGN STORY:

Sharon Bonzaaier’s ink artwork celebrates African animals, from the elusive Black Rhino and revered Dung Beetle to the majestic Lion and speedy Cheetah. Each stroke brings their unique patterns to life, evoking awe and respect for nature’s wonders. Take an artistic safari, immersed in the beauty and harmony of Africa’s wildlife.

HOW IT IS MADE: Each artwork-come-design is a labor of love that begins with Sharon spending many nights painting a myriad of little creatures and plant life. The next step is to scan these beautiful artworks at a very high resolution, ensuring even the most minute detail is captured. Once digitized, the visual elements’ placement is meticulously worked out, following the technical patterns of each WREN item: a laptop sleeve, an iPad cover, a notebook organizer, or a wallet.

HOW IT IS MADE: Each artwork-come-design is a labor of love that begins with Sharon spending many nights painting a myriad of little creatures and plant life. The next step is to scan these beautiful artworks at a very high resolution, ensuring even the most minute detail is captured. Once digitized, the visual elements’ placement is meticulously worked out, following the technical patterns of each WREN item: a laptop sleeve, an iPad cover, a notebook organizer, or a wallet.