There is magic in printing. A piece of paper goes from being plain (and not that plain is not beautiful), but to full of life with detail, colour and animation. It comes alive! Screen-printing is great fun and one of the reasons I became a textile designer – I love how in a few moments a surface can be transformed. When I started Wren the first prints were hand screen-printed by me. I asked a favour of my university and spent a few days pulling squeegees and making magic! Today the process is much more efficient. We print a few hundred sheets at a time and the quality is far superior to my prints but I do not believe the magic is lost.

Let me talk you through the process of each sheet.

First the paper is lined up, exactly.

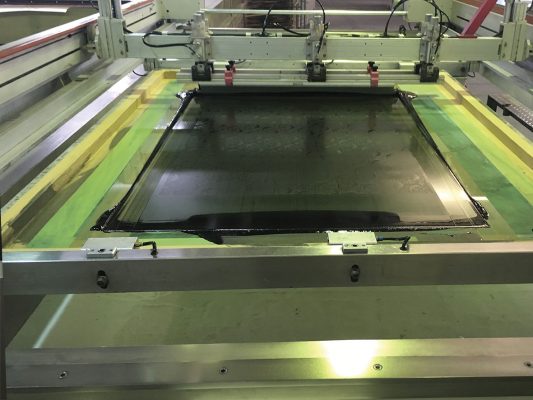

This is transferred underneath the mesh screen (that once upon a time was made of silk), and an automated squeegee (called so becuase of the sound it makes when pulled correctly), pushes the ink through the “stencil” and onto the paper. The table special becuase it “sucks” the sheet of paper down so that it does not stick to the silk-screen when the ink is transferred to it.

The paper is the taken off and transferred to the heat tunnel that “sets” the ink.

When it comes out it goes onto a rack where it dries further.

This shows the process for the Flying Fox print designed by Lauren Fowler. Check out the finished product here.